Professional Comprehensive Building Materials Supplier

Elevated Steel Subfloor System

- Description

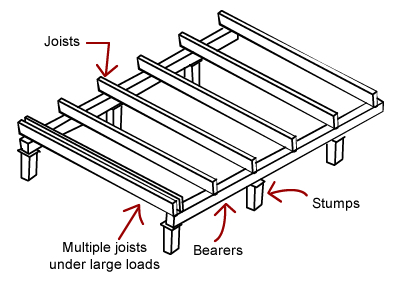

The elevated steel subfloor system is one of the solutions for floor framing. It usually consists of a sub-floor of horizontal beams that support joists (a smaller, closer spaced beam on which the flooring material rests). The bearers in turn sit on stumps which are adjusted in length (either by being partially buried, cut or even adjusted, in the case of adjustable screw-jack stumps) to all be level with each other. This makes such floors particularly useful when building on uneven or sloping ground. A structural floor layer is laid atop this supporting structure. It also offers a wide variety of potential floor covering options, including floorboards.

This lightweight approach has the advantages of usually being lower cost and lower embodied energy than a slab, and is easier to build on a steeply sloping or uneven block. Further, plumbing and other services can be easily run along the joists.

Steel bearers are usually standard I-beam profiles cut to length before being galvanised and/or painted. Some steel systems consist of rolled sheet steel which is formed to make lightweight but strong bearers and joists. Some also come complete with pre-punched screw holes, printed bracket locations and printed joist numbers next to each joist bracket, which correlate with numbers on each joist. Such a system can reduce sub-floor assembly time compared to a measure-and-cut system using standard-length materials.

Prefab sub-floors/floors

With the trend towards prefabrication of some or all of a home, prefab floors have also started appearing in domestic home projects. Bearer and joist systems can be provided in pre-cut lengths ready to bolt together, simplifying construction and reducing the build time on-site. Even faster installation can be had using pre-built floor sections (sometimes called cassettes), which usually consist of a steel or wood frame/joist system with a prefixed flooring material such as particleboard flooring screwed and/or glued into place. These can be particularly useful for multi-storey builds.

Why Elevated floors?Sloping sites can remain largely undisturbed – eliminates cutting, filling and compaction.

Easy under floor inspection (the safest termite prevention method)

Environmentally sound – silt runoff into waterways is reduced

Reduces hidden cost of landscaping to repair site after building completion

Why Steel?

A steel flooring system offers greater durability and strength than traditional timber joists and will provide further cost savings due to it's resistance to pests such as termites and borers.

Steel floor systems can be manufactured to a large span, this allows the number of internal load bearing walls and columns to be minimised allowing greater flexibility in the design of your building.

Steel floor joists will not bend and warp over time and they can withstand moisture, extreme weather events and pests. They are a smart, durable and cost effective flooring solution for your building.

Steel subfloor products are often designed to be modular, allowing for relatively simple installation, and are often used in extensions to existing houses.

How are framed floors installed?

Beam and joist floor frames can be constructed on site or off site and transported in, depending on your foundation. The beams are laid down, grooves are cut in and the joists are then fitted in. Joists should only ever meet each other over the middle of a beam. Because the joists will be evenly spaced throughout the house, the usual starting point is the first two joists in front of the toilet, as this is where you’ll need to allow the most space for the plumbing. Once this has been aligned, the rest of the floor is laid out until it hits the boundary walls.

CONTACT US

Tel | 86-010-88082316

Email | aliciachn@outlook.com

BuildTech Corporation

China Building Materials Building, No. 11

Sanlihe Road, Haidian

Message

Please leave us a message, we will be at your service.

BuildTech Corporation © All Rights Reserved